You have probably noticed a lot more full size off-road company names featured on Axial vehicles as of late. These names are not just another marketing ploy, but instead relationships that Axial has developed to bring you the best products we can. We all know that R/C vehicles are scale representations of full size vehicles, so isn’t it natural that Axial would want to work with full size companies to make their products as accurate as possible? There are obviously components that can not be made to scale, due to the abuse that an R/C vehicle will see, which is way more intense than a full size rig would endure. Take an R/C car and let it tubmle off a 10′ rock, which would be scaled to a 100′ rock in full scale, where a full size vehicle would be literally totaled and made into scrap metal; your Axial rig keeps on ticking. So as you can imagine, not all components scale out just right. The theory however, when it comes to suspension geometry and suspension tuning crosses over extremely well. The Axial staff recently ventured out to Riverside, California to have a technical chat with Dylan Evans and company at ICON Vehicle Dynamics so I tagged along to bring you the scoop!

ICON Vehicle Dynamics is a very unique company staffed with some of the most talented suspension development experts in the nation. Headed up by SCORE off road racing champion Dylan Evans, who also knows rock crawling through his membership of the Poly Goats Four Wheel Drive Club of Cal Poly SLO; Evans and company know a thing or two about how to deal with rough terrain at all speeds. As the name implies, this company focuses on the unique characteristics of each vehicles dynamics (forces causing motion), and how to improve that vehicles ability to tackle rough terrain while significantly improving ride quality.

ICON Vehicle Dynamics is further unique due to their manufacturing process, which all takes place “in house” at their Riverside, Ca facility. The ICON Vehicle Dynamics philosophy demands the use of the highest quality raw materials available, construct the products in the USA and deliver to the consumer the best mix of top-shelf product and customer service. This philosophy has made ICON Vehicle Dynamics stand out in a sea of aftermarket companies and has them labelled as the place to go if you demand the best available.

Cool ICON Decal!

Here is a short video they have as an introductory to their company, check it out!

We started out our visit with ICON Vehicle Dynamics in their large meeting room, where we met with the marketing staff, the general manager, and the engineering staff. This gave both companies an opportunity to discuss the similarities between the two companies. It is amazing how we share the same customers and the same passion for the off road lifestyle

After the meeting, we were off to the warehouse and shop area to check out where the magic happens. I made a few pit stops on the way out of the offices to snap a few pictures of some cool stuff I saw laying around.

Very high tech Bypass shock for off-road racing

Our Axial EXO proudly on display!

The SCX10 Honcho articulated in the office

The line-up of Axial vehicles featuring ICON branding

I decided to peak out the windows from the upstairs office and sneak a few shots of the facility from a bird’s eye view.

Check out all those CnC machines!!

Our shop tour started in the warehouse where they house some of the stock, getting ready to be shipped out, It was amazing to see how many different products they stock, and to hear about how the shelves get refilled almost every day as product is shipped out.

The manufacturing side is what really had us drooling! These guys make some really impressive components.

Everything about ICON Vehicle Dynamics, from their design process, to the manufacturing all the way to packaging, is top notch! We were really looking forward to checking out the shock department, as these guys are known for mastering the ride quality as well as performance.

shock shafts for days!!

Bypass shock bodies freshly welded

Mounting sets ready for assembly

Resivoirs ready to be added

Here is Dylan discussing shock tuning with Axial’s Jeff Johns, Matt Kearney, Brandon Coonce and Jamie Seymour.

Not sure if you caught our blog on the SCX10JK where we installed the ICON suspension system (If not click here to read it), but we were running and testing some of their compression clicker shocks. We figured since we were here, we should go ahead and remove them to see how they were doing, as well as make a slight valving adjustment. We pulled the SCX10JK up in the shop, and Adrian (shock building master) got to work.

The first step was to remove all of the shocks

Once the shocks were off of the vehicle, Adrian set up the shock dyno, yes I said shock dyno! This is where these guys take technology to the next level to put their experience into scientific numbers.

The numbers from the shock are then placed on a graph in real time on a computer screen

The objective of the change was to make the shocks 25% lighter on the compression valving to make the clickers more effective through their range of adjustment. We found that the SCX10JK never went above 6-clicks even in the harshest of terrain. We had the pleasure of watching Dylan and Adrian work their magic on the Dyno and out in the shop as they dissassembled and re-assembled the shocks for the adjustments. We will let the pictures tell most of the story…

The shock pistons look quite a lot different than the average R/C shock piston. These pistons have valve shims that are designed to flex out of the way of piston holes to let fluid pass. The one unique feature of full size ICON shocks is their very drastic difference in tunability between compression and rebound settings. Were we would normally make changes in the R/C world with oil viscosity, these guys make changes with shims. They have been doing it long enough to know what shim stack will make the desired change, and only have to tear them down once and get it dialed in perfect!

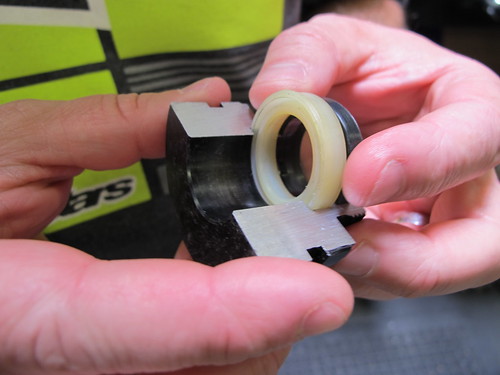

The seal heads are similar to the R/C versions, here is a cut away version of the ICON seal head

Once the shocks are completely reassembled, it’s back to the dyno for a comparison check from the original numbers

Dylan fires up the dyno and then checks the graph on the lap top and confirms they are good to go!

While Adrian re-installs the shocks on the SCX10JK, Dylan, Brandon and Matt discuss some of the suspension tuning Dylan has been doing on his Axial EXO and Wraith. Dylan is also an R/C enthusiast and really gets into the deep technical theory conversation with Matt and Brandon.

It was extremely cool to be a fly on the wall while the head of R&D from both of these companies exchange theories and ideas. It will be very interesting to see where this corroboration leads in the future. One thing for sure, with Partners like ICON Vehicle Dynamics, there will not be an issue gathering insight into the full size world when developing the next Axial vehicles.

Thank you Dylan and Crew at Icon Vehicle Dynamics, we appreciate your hospitality, and look forward to future visits!

Please check out ICON Vehicle Dynamics on the web here.

By Axial R/C Inc. –

Story by: Recce01

Photos: GCRad1